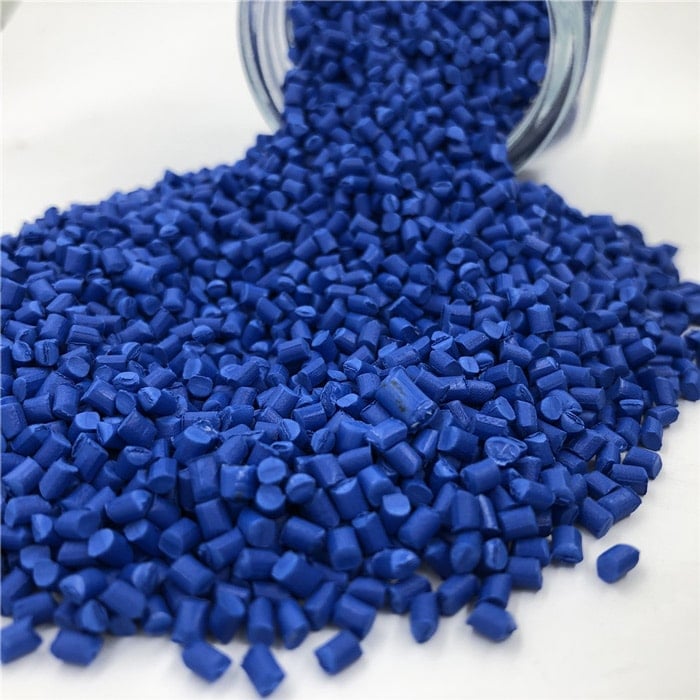

Hard pvc compound

The hard PVC compound product of this company has competitive advantages and quality compared to competitors in its production, it can be produced based on the customer’s request, and due to the additive manufacturing of the products related to the PVC industry of this company, it can be Have a good situation for customers.

What is PVC Compound?

read article about : what is pvc compound

Hard pvc compound application

- Wall covering production

- Production of pipes and fittings

- production of edge band

- False wall production

- Wire and cable production

Characteristics of hard compounds

Features of hard PVC compound include the following:

- High hardness and strong mechanical strength

- High resistance to breakage and impact

- High resistance to atmospheric factors such as sun, rain and adverse weather conditions

- Ability to process and produce with different methods such as injection, positive pressure and negative pressure

- Ability to increase resistance and beauty features by using different colors and various additives

Masterbatch compound can be used in many industries due to its diverse and useful properties. For example, the use of polymer compounds reduces the consumption of raw materials in the production of polymers, and as a result, the cost of production also decreases. Also, the use of this material can improve the quality characteristics of polymer products such as mechanical resistance, transparency and precise color.

Masterbatch polymer compound

Masterbatch Polymer Compound is a chemical substance that is used as a colorant, calcifier, tonic or antioxidant for modified polymers. This material includes basic polymers, fillers, dyes and other additives.

In the masterbatch polymer compound production process, raw materials such as the main polymer, fillers, dyes, and additives are prepared separately and finally combined to obtain a masterbatch polymer compound.

The use of Masterbatch polymer compound has been highly regarded due to its features such as color accuracy, increased mechanical resistance, improved transparency, and reduced production costs. Also, the use of masterbatch polymer compound can improve the processing efficiency and ability to produce modified polymers.

The use of masterbatch polymer compounds is very common in various industries. In the automotive industry, this material is used to produce internal and external car parts such as dashboards, windows and doors. In the packaging industry, masterbatch polymer compound is used to produce moisture and heat resistant packages. Also, this material is used in electronics, construction, household appliances and medical industries.

Among the other advantages of using masterbatch polymer compound, we can mention the reduction of production cost, improvement of efficiency and reduction of production time. Also, this substance can be useful as an alternative to using raw materials in the production of polymers, improving the environment and reducing environmental pollution.

Masterbatch polymer compound applications

Production of car parts such as windows, doors, dashboards, etc.

Production of moisture and heat resistant packages

Production of industrial materials such as polymer pipes, industrial parts, etc.

Production of household appliances such as internal parts of refrigerators and washing machines

Production of medical devices such as surgical instruments and medical implants

Production of consumables such as sanitary ware and disposable containers

In general, masterbatch polymer compound is used as an efficient and useful chemical in many industries and improves the quality characteristics and reduces the production cost of polymer products.